Know-how

Good understanding of the use and destination of the parts we manufacture is a prerequisite for the development of the expected product. This will have direct consequences in the choice of materials and / or processes that we will implement.

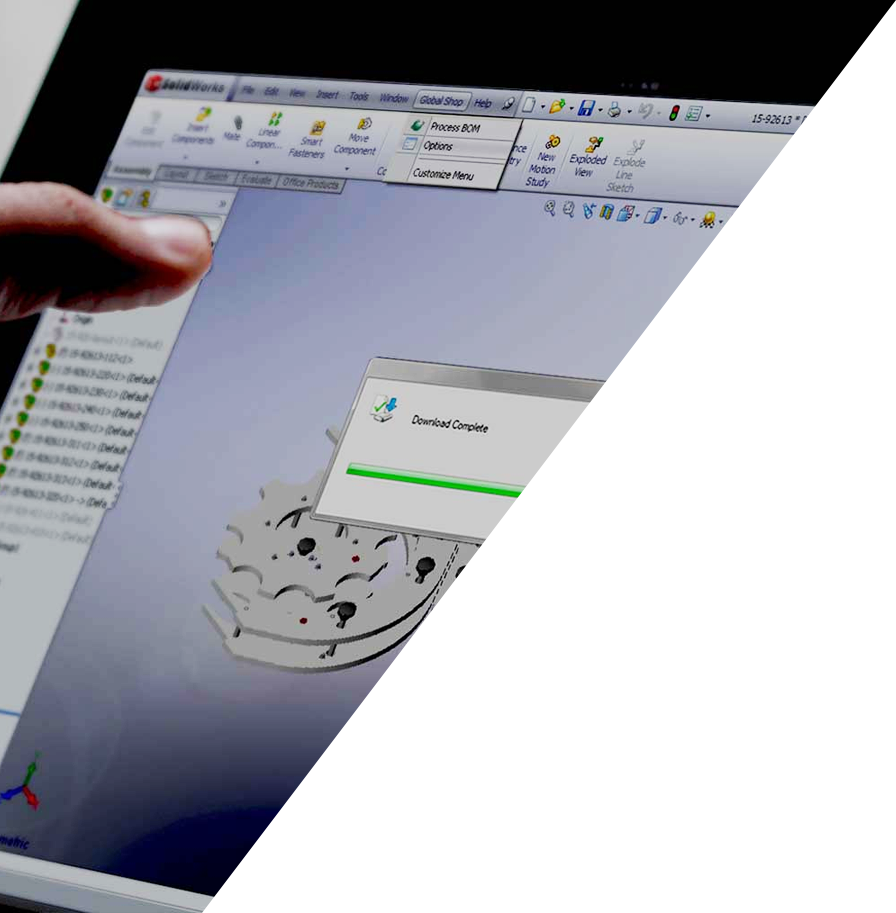

Digitization : key step in the search for performance

The use of a latest generation CAM software for the design, the modeling and the programming of your custom-made parts is a major asset for responsiveness and optimization of the manufacturing costs.

choosing the most suitable material

In line with an ever evolving industry, we make a point to always offer the material most suited to the needs of our customers. That's why we source with the biggest European suppliers to ensure the best quality, excellent reproducibility and real traceability.

The semi-finished products (plates, tubes, rods ...) that we work with are generally standard thermoplastics (PE - PVC - PA6 - PET - POM - PMMA) or high performance (PTFE - PPS - PEEK - Etc.). The technical specifications (safe load, temperature of use, dimensional tolerances, dielectric properties ...), the durability (the number of cycles, the resistance to hydrolysis) or traceability (such as Food Grade certification for example) are all factors that will influence the choice of material as well as the final cost.

The other vital aspect: the adequacy of the process

The series quantity will have a defining influence on the choice of the process. Indeed, the production of 1, 10 or 500 parts can lead to three different processes for the sole purpose of defining the most economical manufacturing range.

For this we have a range of machines to adapt the machining to all shapes, from various semi-finished products (plates, tubes, rods ...).

- Cutting / profiling: routers, circular saws, band saws, jointers, planers, digital saws with horizontal tray (large sizes).

- Turning / Milling: traditional and digital machines (lathes, milling machines, drilling machines, CAM machining center).

- Other processes: on demand, we are also able to provide assembling, folding (up to 1200 mm in length) and welding of rigid plastics.